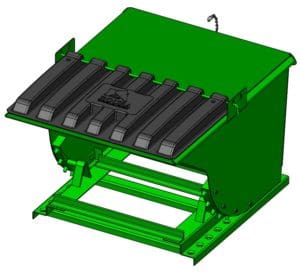

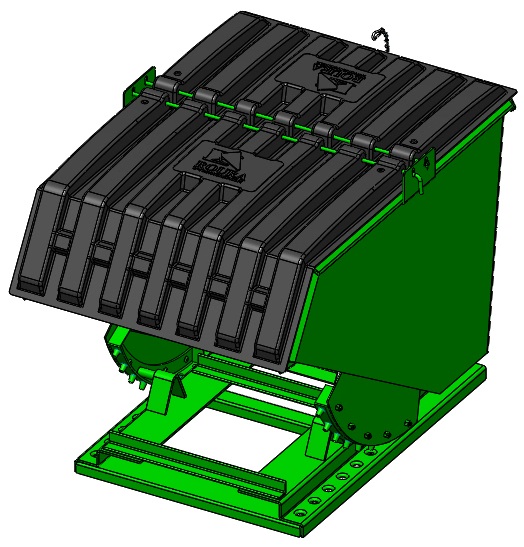

What is a meat hopper? A meat hopper is a specially designed self dumping hopper suited for the handling of food, meat scraps and organic waste.

Businesses like restaurants, grocery stores, and other establishments tend to generate a lot of food waste during the course of a day. The dump hopper allows for the meat scraps and other waste to be disposed of easily and efficiently to ensure a pleasant environment for both customers and staff.

Features:

- Well made sliced, ejected trunnion passage with taper pins for best wear confrontation.

- All meat hopper are constructed of 3/16″ & 12-gauge carbon steel.

- Optional molded plastic lids add strength and elasticity.

Benefits of a Hopper For Meat Scraps

Fast removal prevents the accumulation of unpleasant odors and smells which can damage the reputation of your business. Inefficient waste removal can also land you in legal trouble if a health inspector determines that the issue could impact the health and safety of your staff or customers.

Self-dumping meat hoppers offer the best possible solution to food waste removal for many types of businesses. All types of food and organic waste can be deposited into these hoppers, which are available in one and two cubic yards depending on your waste handling needs. Once the hopper is full, it can be lifted, moved and dumped via a forklift if necessary for easy disposal.

Contact our engineering and sales staff today for more details on load capacities, sizes and customization options.

Recommended Food Processing Hoppers:

-

H-PLDA-410

Load Capacity: 6,000 lbs. Volume Capacity: 1 1/2 cu. yd. Dimensions: 65" x 47" x 49"Read more -

H-PLDB-205

Load Capacity: 6,000 lbs. Volume Capacity: 3/4 cu. yd. Dimensions: 57" x 46 1/2" x 36 1/2"Read more -

Stainless Steel Hopper

Load Capacity: Capacity Varies Volume Capacity: Capacity Varies Dimensions: Dimensions VaryRead more -

Galvanized Steel Hopper

Load Capacity: Capacity Varies Volume Capacity: Capacity Varies Dimensions: Dimensions VaryRead more

Stainless Steel Hoppers

Corrosion can be a concern with the disposal of food waste or caustic chemicals. Over time, waste materials may break down your hopper and lead to expensive repairs and maintenance. If damage is too severe, you may even need to replace the hopper sooner than expected.

That’s precisely why these meat and food hoppers are made from stainless steel. Stainless steel is highly resistant to rust and corrosion. This material also doesn’t require a protective topcoat to ward off damage like other options.

When it comes to the self dumping steel hoppers bin itself, the design is meant to be as rugged and sturdy as possible. Bins are constructed from 3/16 inch and 12-gauge carbon steel for maximum durability, which ensures an extended lifespan. These specs mean you get year after year of service out of your equipment, making these hoppers a smart investment.

As for the forklift channels, which are where lifting equipment will make contact with the bin, they’re also designed for optimum efficiency. They easily fit all standard forklift attachments to ensure compatibility with many types of equipment. The ejected trunnion passage is also created to minimize wear as much as possible. Minimized wear means less hassle when it comes to maintenance, repairs, or replacement.

Do Meat Hoppers Come with Lids?

Customization is key to ensure your equipment serves your business the best it can. While you can opt for a hopper without a lid, they actually offer quite a few benefits. This is especially true when the lid is designed to be rugged and dependable.

Lids are constructed from highly durable molded plastic. This plastic can defend against weather elements, including rain and wind. It can also prevent pests from getting inside the hopper.

Mice, rats, and insects can make their way inside waste handling equipment, but using a dependable lid can prevent a huge mess and possible sanitary issues. Lids also prevent any safety problems or other concerns when it comes to the public.

While lids are undoubtedly durable, they’re also quite flexible. This stops them from breaking or cracking during operation or after repeated exposure to the elements. Lids are also extremely lightweight, so they won’t add too much extra weight when the hopper is nearly full.

What Are the Options for Lids?

There are actually quite a few options when it comes to hopper lids and coverings. While having some type of covering is recommended, choosing the right one ensures this device meets the needs of your business. A wide selection of coverings means that all businesses can find a configuration that best suits their specific application:

Watertight Types A, B, and D

All watertight covers are designed to prevent water intrusion into the hopper. Watertight covers A and B feature a 14 gauge center hinge, as well as a continuous hinge across the top of the device. Watertight cover D features a double hinge with a continuous hinge across the top.

All three feature a drain channel under the hinge. Type A comes with an open front and back, while Type B features a fixed back and open front. Type D features an open nose and back with a fixed center cover.

While all watertight covers are designed to be used on all models, Types A and B may not be compatible with hopper models 680 and above. However, watertight cover type D can be used with any model.

Plastic Lids

Plastic lids are available for the model rotator boxes only, which are designed with optimum durability in mind for heavy-duty jobs. They’re compatible with 1/2, 3/4, 1, 1 1/2, and 2-yard models. The heavy-duty polyethylene double-wall construction ensures protection from the elements. Plastic lids are also designed with a top crown to ensure good drainage. They’re also easy to open to ensure swift access when needed.

Vinyl Tarps

The waterproof vinyl tarp features a fitted front to keep the cover in place. It also has a bungee cord fastener in the back of the cover for easy tightening. This cost-effective option ensures your business is fully compliant with environmental regulations concerning rainwater runoff. Vinyl tarps are available for all hopper models.

Mesh Tarps

Like the vinyl tarp, the mesh tarp also features a fitted front and bungee cord fastener in the back of the cover. It’s designed to stop food waste and other materials from falling out of the hopper as it’s being transported from one place to another. It’s also compatible with all models of hoppers.

What Are the Benefits of a Meat Hopper?

When making an investment in your business, you must consider whether the costs outweigh the benefits. Fortunately, investing in a food waste hopper offers numerous benefits, making it an ideal purchase for a variety of business owners dealing with food waste on a regular basis.

When you purchase a hopper for meat scraps, you can rest assured of safe, speedy disposal of waste at your restaurant or grocery store. You can also look forward to versatility. Along with numerous types of organic waste, hoppers can also be used to dispose of recycled materials, plastics, wood, metal scraps, aluminum, fluids, and many others.

The design of hoppers also includes safety considerations for many waste disposal scenarios. Forklift operators can rest assured of an efficient transportation and removal process thanks to this smart design. This is true even when disposing of large amounts of waste, or waste that’s irregularly shaped.

Durable Dump Hopper Materials

The materials chosen for the construction of waste disposal equipment offer unbelievable durability. In addition to withstanding rain, snow, and sun exposure, they also hold up against the continuous wear and tear of transporting and dumping waste materials. This durability is present across all applications.

There are also many customization options to choose from. You can specify size, volume, high vs. low profile, special attachments, and more. You can choose to modify an existing model to meet your needs. You can also have your hopper design completely customized from the ground up for unique applications.